EIS assembles brightest British minds to power medal hopefuls

While much of the preparation for the Tokyo Games was focused on methods of keeping athletes and their support staff cool in the high temperatures in Japan, the English Institute of Sport (EIS)’s Performance Innovation team were quietly working on a project to achieve the opposite outcome.

Having warm muscles is a well-established component of elite sport, particularly power and speed sports where there is a direct relationship between muscle temperature and maximal power production. The challenge arises when athletes complete their warm-up but have a lengthy wait to keep their muscles at an optimum temperature until their competition.

Heated garments are not a new solution to this problem; track cyclists at London 2012 wore battery-powered ‘hot pants’ in the warm-up area in the Velodrome and various iterations have existed since. However, the EIS approached this differently for Tokyo given the advances in heater technology and masterminded a truly novel solution in collaboration with industry experts.

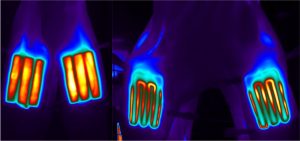

A group of leading British industry and academia was assembled in early 2017 and together with the EIS’s Performance Innovation team, conceptualised and produced a garment that generates heat using printed functionalised graphene ink and incorporates pioneering electronic circuitry to produce temperature regulated panels.

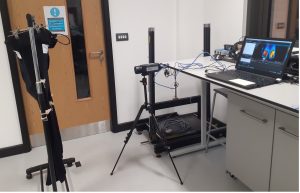

The Applied Sports, Technology, Exercise and Medicine (A-STEM) Research Centre and the Welsh Centre for Printing and Coating (WCPC) at Swansea University invented and developed the original flexible heater that can be printed directly onto fabric, using flexible functionalised graphene ink, which was manufactured by global advanced materials company Haydale using their patented HDPlas process. Once a working lab-based prototype was developed by Swansea, ScreenTec printed the graphene panels, and the EIS recruited Newbury Electronics, who were instrumental in developing advanced electronics that were fit for purpose for the challenging environments the athlete would use the garments in.

Newbury Electronics collaborated with Crucible Design to develop electronics housings and an intuitive user control which enabled the athletes to control temperature range and zonal control of the heater panels. Sew Systems, specialists in garment design and manufacture, finally assembled the garments. All these British collaborators, project managed by the EIS Performance Innovation Team, overcame the challenges faced through Brexit and Covid-19 to successfully develop a concept garment which was used at the Tokyo Games, including by a medal winner.

The concept garment can generate heat up to 50 degrees. Crucially, it warms up very quickly and spreads heat uniformly to targeted muscle groups, allowing athletes to keep specific muscles at a pre-defined temperature, right up until their competition.

Director of Performance Innovation at the EIS Matt Parker said: “The muscle warming project, led by the EIS Performance Innovation team, is an excellent example of collaborating with British Industry and academia to accelerate the development of new and novel apparel and technology solutions. Our British suppliers have proven their ability to deliver technically difficult solutions in the most challenging Covid-19 conditions to tight deadlines.

“This has been a real success story, and shows the power of British industry, something the EIS will continue to harness to help British athletes prepare for future competitions on the world stage.”

Find out more about the collaborators on the muscle warming project:

Welsh Centre for Printing and Coating (WCPC)

Swansea University

Haydale

Newbury Electronics

Crucible Design

Sew Systems

Screentec